2 Homemade stand-tester for testing transmission solenoids -Transmission Solenoid Tester DIY-

Test Trasmission Solenoid allows you to carry out a professional performance test of automatic transmission and DSG solenoids in any conditions, even in the garage or at home.

The cost of the Transmission Solenoid Stand is about $300. To date, the capabilities of the Solenoid Tester DIY allow you to work with all known types of solenoids. Restrictions only in adapters.

The device is designed to visually check the performance of automatic transmission (AT) and DSG solenoids and is a cheap alternative to industrial solenoid testers. I personally use these devices to repair "old-style" 6T40 solenoids at home in a 17-storey building for 10 years.

The principle of operation of a home-made stand for testing solenoids is to conduct an air test of the solenoid and compare the graph of the tested solenoid with the graph of the reference solenoid of the sample. For a specific solenoid model, adapters are required, which you can print yourself on a 3D printer by creating a drawing or buying it from us. The cost of a file for printing on a 3D printer in STL format is $10 per transmission model. That is, if the 8HP45 transmission uses 3 different types of solenoids, then for $10 you get three STL files for three types of solenoids.

Here it is described in more detail.

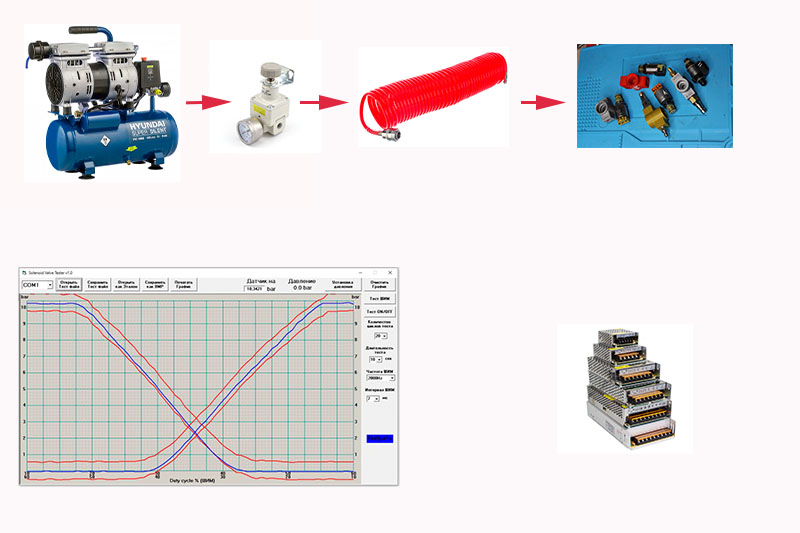

The composition of the stand for testing automatic transmission solenoids can be conditionally divided into three parts - air, an adapter for a solenoid and an electronic part.

The air part is located on the compressor and its task is to maintain air pressure with an accuracy of 0.5 atmospheres. For this, a precision pressure regulator is used. You can read more about it on the assembly page.

1 standard pressure regulator included with the compressor.

2-valve that prevents air from escaping during a pause in the solenoids test.

3-high precision (precision) pressure regulator IR2020

The adapter for checking the solenoid is a model printed on a regular FDM 3D printer. You can model the file yourself (later I will post a video on how to do this) or buy it ready-made here.

The electronic part consists of an electronic device that is inserted into the USB port of the computer, a control program installed on the computer and an electronic pressure sensor. It is also desirable to install an electronic pressure gauge and a mechanical pressure gauge to adjust the solenoids during repairs..

Advantageous differences between Transmission Solenoid Tester and industrial ones are:

1.Low cost of equipment. (the calculation is carried out without the cost of a computer!)

a) Transmission Solenoid Stand DIY Program plus Test Device Test Device Board Assembled (Located inside the Test Device) - $100

b) Compressor (the most expensive purchase). I use a HYUNDAI HYC-1406S quiet compressor. This compressor has a low noise level during operation and does not require additional noise insulation of the room. Approximate noise levels are shown in the photo ... ... average cost is $ 130.

c) Power supply 12 volts 13-16 amperes or 200 watts (cost about $ 20). Such power supplies are used in LED lighting systems.

- d) Precision pressure regulator. You can use the IR2020 for about $ 20, you can buy it here (not advertising). I bought my VEX1330 precision regulator for $ 23 on Ebay. Pay attention to the inlet and outlet hole diameters and the diameter of the hole for the pressure gauge (it can be drowned out as unnecessary).

- e) Fittings and adapters totaling $10.

- f) 3D printer for printing adapters for various solenoids (you can use a friend's printer or find a workshop in your city). With an approximate weight of one adapter of 40 gm, the cost of a filament is 40 rubles. per 1 piece (with an average cost of a filament of 1000 rubles per 1 kg).

- The total cost with the compressor is about $300.

2. In principle, the Solenoid Tester is a universal device for all types of automatic transmission solenoids and DSG. It is only necessary to design and print the STL file of an adapter for a specific solenoid.

You can also buy an STL file inexpensively ($10) for a specific transmission. This price includes STL files for ALL solenoids. For example, in the 8HP45 transmission, 3 types of solenoids and all three STL files will cost $10

3. The ability to create solenoid reference graphs yourself using known working solenoids as references or purchase a reference graph for $10. The price includes all reference graphs for one transmission. For example, 3 reference graphs for an 8HP45 automatic transmission will cost $10.

4. Since air is used in the tests, there is no oil - this is a huge plus - the cleanliness of the workplace. I use this tester at home in an apartment building, having allocated one of the rooms for testing solenoids. (In the future, I plan to add a temperature sensor and a heater to the program to be able to test solenoids in hot oil in a garage repair).